Digital Patterning

The Digital Patterning is designed through computer graphics. It can automatically complete processes such as drawing, cutting and marking, and is operated by our professional and experienced staff. This equipment has greatly shortened our plate-making time and improved production efficiency. Precise design reduces material waste, lowers costs and improves efficiency at the same time.

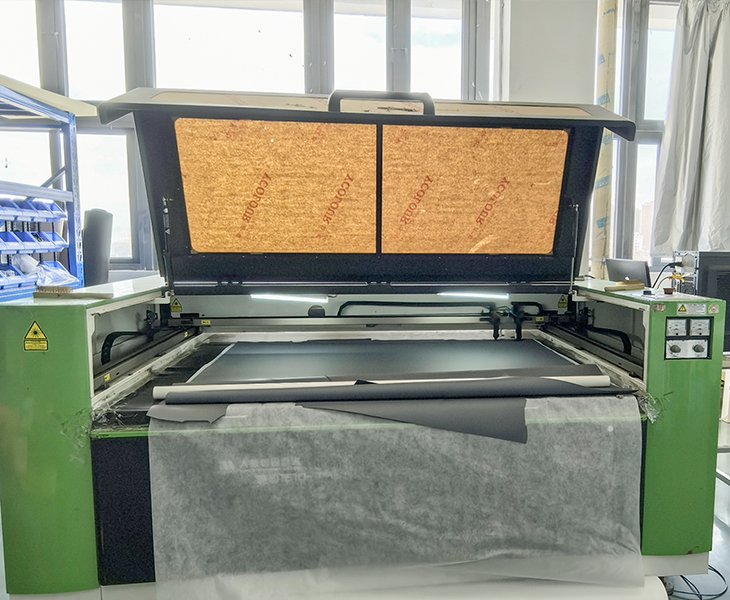

Laser Cutting

Laser cutting is a high-precision technology. The cutting edge is smooth and burr-free, no secondary processing is required, and production efficiency is significantly improved. Compared with traditional mechanical cutting, laser cutting is faster and more flexible, and can easily process complex patterns and irregular parts. Exquisite craftsmanship combined with innovative technology ensures that every piece of work achieves excellent quality.

High Frequency Welding

High-frequency welding uses high-frequency current to fully fuse TPU or PVC fabric. This completely eliminates the risk of water seepage through needle holes in traditional sewing processes, meeting the IPX6-IPX8 waterproof sealing standards. The finished products perform exceptionally well in terms of tear resistance, cold resistance, and heat resistance, and are particularly suitable for TPU materials. Its fusion strength is significantly better than that of PVC. Currently, we have been able to develop complex molds to meet the demands.

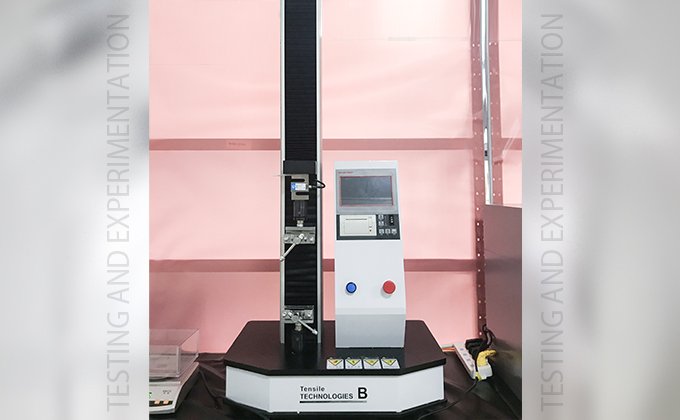

Testing and Experimentation

In order to ensure the reliability of the waterproof bag in various outdoor environments, we conducted a series of rigorous waterproof tests.

Simulating heavy rain conditions, the fabric’s hydrophobicity and moisture resistance under continuous impact are evaluated to ensure that rainwater cannot penetrate.

The product is tested for adhesion and stability between fabrics and between webbing and fabrics after more than 50 vibrations when loaded with a 30-catties weight.

We use professional equipment to repeatedly open and close the zipper to simulate long-term use scenarios. The zipper has undergone more than 5,000 high-intensity tests to keep the cable smooth, without sticking teeth or damage, ensuring the durability and reliability of the product.

Professional tear strength testing ensures that the material has excellent tear resistance when subjected to load or accidental friction, avoiding waterproof failure due to damage.